How to configure a Neutralizer into your water treatment system

If you use multiple treatment systems for your well or city water, you have probably wondered whether their order of installation affects the final quality of your treated water. The answer is yes, the order of your treatment systems can be a factor in determining the effectiveness of your systems. One customer using an iron filter and water softener for his well water recently wrote to us explaining that he wanted to add a neutralizer to this configuration, but was unsure where on his line to install it.

Parts and Order of Installation

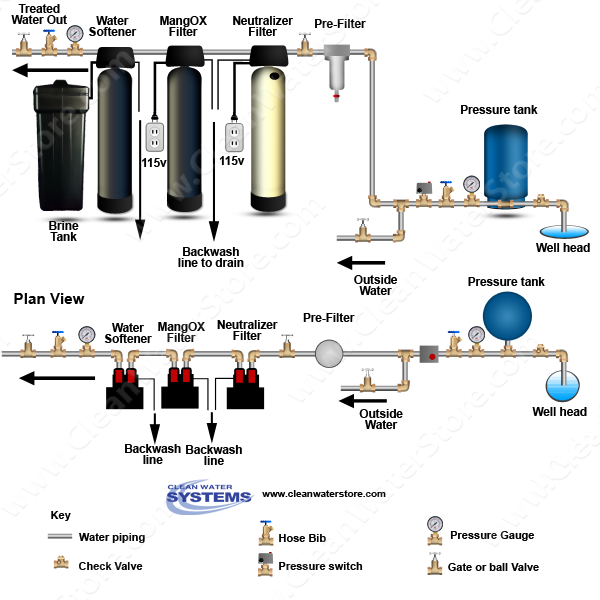

We recommended that he install his neutralizer first, followed by the iron filter and then the water softener. We also suggested that he use a pre-filter such as a Lakos Twist II Clean sediment filter to prolong the life of the media in the neutralizer and other systems. Here is a handy diagram to illustrate how these systems should be installed for maximum effectiveness:

Here's a bit more information on the systems mentioned above:

We recommend Lakos Twist II Clean sediment filters because they are effective pre-filters that are very easy to use and clean – simply twist the handle at the top of the filter to begin the patented reverse flushing action, and watch your filter backwash itself from the inside out.

Water Neutralizer

For the neutralizer, we recommended a calcite neutralizer 7000-SXT. These filters include instructions for using the calcite and Corosex media, and can be installed by any person familiar with basic plumbing. They also require little maintenance: simply backwashing once a week for about 8 to 10 minutes will keep the calcite operating effectively, and since the Enpress tank with Vortech distributor allows for backwashing with 30% less water usage than other neutralizers, you'll be saving money on water and energy with each backwash. Other features include an easy-to-use bypass valve and top-fill plug, which make adding additional calcite as simple as can be, and an advanced internal screen which eliminates the need for a gravel base (this is how the system is able to backwash using much less water than other neutralizers, as mentioned above).

We hope this information helps you achieve the most efficient configuration for your water treatment systems. If you have any further questions or comments about water or water treatment, e-mail us at [email protected] or leave a comment on our Facebook page. Thanks for reading!

>